Learn more about Water Filtration

Introduction and Outline: Why Water Filtration Matters

Safe drinking water underpins health, confidence, and comfort. For many households, municipal treatment is reliable, yet residual chlorine, aging pipes, seasonal runoff, or hard water minerals can still affect taste, odor, and appliance longevity. Private wells face their own challenges, from agricultural nitrates to naturally occurring arsenic. Globally, water quality varies widely, and even in highly regulated regions, distribution infrastructure and local conditions shape what reaches your tap. Filtration provides a practical, verifiable last step: you identify risks, select the process that targets them, and maintain it on a schedule you control.

Before we dive deep, here’s the map of what you’ll learn next, so you can skim to what you need or read end‑to‑end for the full picture:

– Understanding your water: sources, contaminants, measurements, and testing basics.

– Filtration technologies explained: what each method removes, where it fits, and trade‑offs.

– Choosing a system: point‑of‑use vs point‑of‑entry, sizing, installation, and real‑world costs.

– Daily use and upkeep: replacement intervals, performance checks, and troubleshooting.

– Sustainability and future trends: reducing waste, smarter monitoring, and material innovation.

Two quick principles guide this article. First, treat filtration as a match game: pair a known concern with a method proven to reduce it. Second, factor maintenance and lifetime cost from the start; filters are not one‑and‑done devices. The outcome we’re aiming for is straightforward: clearer water, predictable performance, and fewer surprises. Along the way you’ll see concise comparisons, approximate ranges you can use for budgeting, and examples that translate lab terms into kitchen‑sink decisions. Keep your current setup in mind as you read; your final plan should be specific to your water, your home, and your priorities.

Understanding Water Quality and Contaminants

Water quality begins with source. Surface water (lakes, rivers) often carries seasonal sediment, organic matter, and microbial load that fluctuate after storms. Groundwater (aquifers, wells) is typically clearer but may accumulate dissolved minerals such as calcium, magnesium, iron, and manganese, or naturally occurring elements like arsenic and fluoride. Distribution systems add a final twist: corrosion in old plumbing can leach metals, while disinfectants control microbes but influence taste and by‑products.

It helps to categorize contaminants to match them with treatment. A practical breakdown includes:

– Physical: sediment, rust, dirt; measured as turbidity in NTU (nephelometric turbidity units). Clear water often sits below 1 NTU.

– Chemical inorganics: hardness minerals (expressed as mg/L as CaCO3), iron and manganese (can stain fixtures), lead and copper from pipes (commonly measured in ppb).

– Chemical organics: pesticides, solvents, and taste/odor compounds; some are volatile and adsorbable.

– Disinfection agents and by‑products: chlorine or chloramine and their reaction products; important for taste and compliance.

– Biological: bacteria, protozoa, and viruses; measured indirectly via indicators (e.g., total coliforms).

– Emerging concerns: microplastics (micrometer‑scale particles) and persistent chemicals such as certain fluorinated compounds.

Standards and guidelines set context. Many regions maintain a lead action level around 15 µg/L (ppb), arsenic limits near 10 µg/L, and nitrate at 10 mg/L as nitrogen. Free chlorine residuals at the tap often range from about 0.2 to 1.0 mg/L to maintain microbial control. Hardness above ~120 mg/L as CaCO3 is commonly regarded as “hard,” which encourages scale on heating elements and fixtures. None of these numbers alone tells you the story, but together they inform what to test and treat.

Testing can start simple and scale up. Home kits can quickly screen for hardness, chlorine, pH, and sometimes metals. Utility water quality reports summarize system‑level data, while private wells typically benefit from periodic lab analysis, especially after floods, nearby construction, or agricultural changes. A sensible approach is to combine a baseline lab test with quick checks over time. That way, you catch trends—like rising hardness or seasonal turbidity—and you select filtration that is neither overbuilt nor wishful thinking.

Filtration Technologies Explained: What They Do and Don’t Do

Think of filtration methods as tools in a kit, each tuned to a specific job. Sediment filters are the simplest: depth or pleated cartridges, typically rated from 5 to 50 microns, grab sand, rust, and silt to protect downstream components. They don’t remove dissolved substances, but they improve clarity and help carbon or membrane systems operate efficiently by preventing clogging.

Activated carbon is the workhorse for taste, odor, and many organics. With huge internal surface area, carbon adsorbs chlorine, some disinfection by‑products, and a wide array of volatile compounds. Granular forms offer higher flow and capacity, while solid block designs often achieve finer particulate removal. Carbon’s limits are equally important: it does not reliably remove dissolved minerals like nitrates or hardness, and performance depends on contact time and cartridge condition.

Ion exchange swaps ions in water for benign alternatives. A common residential application is softening: exchanging calcium and magnesium for sodium or potassium to prevent scale. Specialized resins can target nitrate, arsenic in certain states, or heavy metals, but they require correct pre‑treatment and regeneration schedules. Softening improves appliance efficiency and soap performance but does not purify in the broad sense; pairing with carbon or another barrier often yields the most balanced result.

Membrane processes divide the dissolved world by pore size. Microfiltration (roughly 0.1–10 µm) and ultrafiltration (around 0.01–0.1 µm) are strong barriers to particles, cysts, and many bacteria. Nanofiltration tightens the net further, reducing multivalent ions and large organic molecules. Reverse osmosis operates at ~0.0001 µm equivalent, rejecting a high percentage of salts, metals, and many organics, delivering very low total dissolved solids at the point of use. Trade‑offs include lower flow, storage tanks, and a waste‑to‑product ratio that commonly ranges from about 1:1 to 3:1, depending on pressure and design.

Disinfection technologies focus on inactivation, not removal. Ultraviolet systems deliver a germicidal dose (often measured at 254 nm) that deactivates microbes without chemicals or residual taste. They require clear water to work well; sediment or color can shield organisms, so pre‑filtration is essential. Oxidation methods, such as aeration or contact with oxidants, can transform problematic species (for example, changing dissolved iron into a filterable form), often followed by filtration for capture.

No single technology covers everything. The most dependable setups combine stages: sediment for protection, carbon for taste and organics, and a targeted barrier—ion exchange, membrane, or UV—based on specific contaminants. The key is alignment: choose the simplest chain that delivers the reductions your test results call for, and nothing extraneous that adds cost without benefit.

Choosing and Maintaining a System: From Goals to Daily Use

Selection starts with clarity on goals, not gadgets. Identify what you want to change: taste and odor, scale, lead risk, nitrates, or microbial assurance. Match those goals to test results, then pick a point in the home where treatment makes sense. Point‑of‑use (POU) systems sit at a single location—such as an under‑sink unit feeding a dedicated faucet—while point‑of‑entry (POE) systems treat all incoming water to protect plumbing and fixtures.

Here’s a practical path you can follow:

– Define outcomes: “Reduce chlorine taste,” “Protect water heater from scale,” “Lower dissolved solids for coffee.”

– Check constraints: space under the sink, available power for UV, drain access for membranes, and desired flow rate.

– Choose scope: POU for drinking and cooking, POE for whole‑home hardness or sediment.

– Plan maintenance: cartridge sizes, filter life in gallons, simple access for replacements, and reminders.

Typical residential options and considerations include:

– Pitcher and faucet‑mounted carbon: quick improvement in taste and odor; low upfront cost; frequent cartridge changes and modest flow.

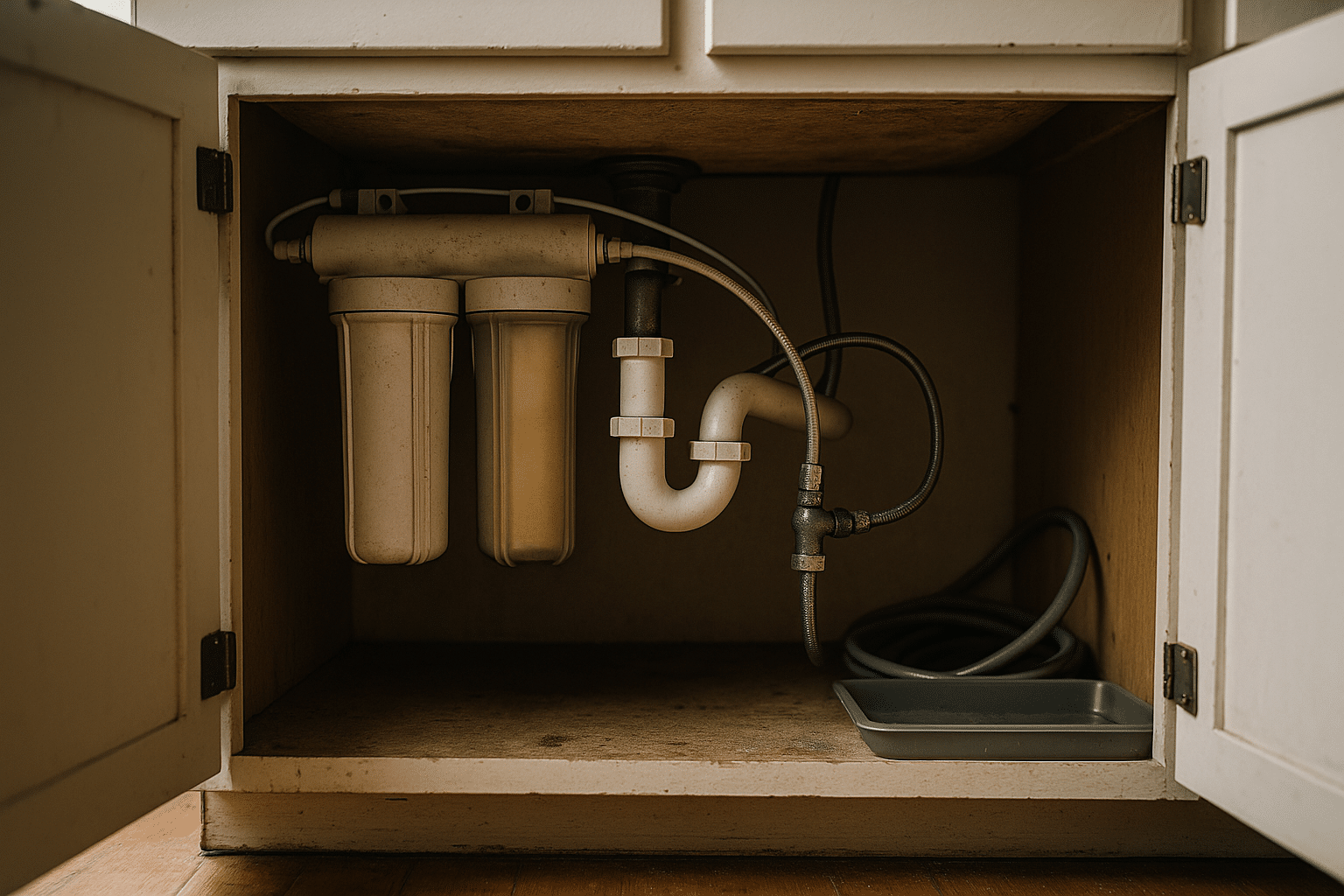

– Under‑sink carbon or composite blocks: higher capacity, better contact time; can pair with a dedicated tap; medium upfront and recurring costs.

– Reverse osmosis at POU: broad reduction of dissolved species; storage tank for on‑demand use; requires drain connection and periodic sanitization.

– Whole‑home sediment and carbon: protects appliances, improves aesthetics at every tap; may not address dissolved contaminants; sizing by maximum household flow is critical.

– Softening (ion exchange): reduces scale and soap use; requires regeneration, salt or alternative media, and routine checks; often paired with carbon for taste.

Maintenance is where performance lives or dies. Filters have finite capacity, typically specified in gallons or months—always whichever comes first under your usage. Warning signs include noticeable pressure drop, return of chlorine odor, or changes in taste. Simple routines help:

– Note install dates and expected change intervals on the housing with a marker.

– Keep spare cartridges on hand to avoid stretching life.

– Sanitize housings during cartridge changes to control biofilm.

– For membranes, monitor flow and, if applicable, product‑to‑waste ratio; low temperature or low pressure reduce efficiency.

Budgeting is best done over five years. Add equipment cost, replacement media, and a small allowance for parts like O‑rings. A modest under‑sink carbon setup might total a few hundred in year one and a steady, predictable amount each following year, while a multi‑stage system with a membrane and tank will be higher but may replace bottled water purchases and plastic waste. The right system doesn’t strain your routine; it blends into it, delivering dependable water with a quick quarterly check and scheduled swaps.

Sustainability, Future Trends, and Final Takeaways

Filtration can support sustainable habits when designed thoughtfully. Start with source reduction: if taste and odor are your primary concerns, a well‑sized carbon stage may replace the habit of buying packaged water, cutting transport emissions and plastic. For hardness control, efficient regeneration and mindful settings reduce salt and water use. Membrane systems have improved waste ratios and can be tuned with permeate pumps or better recovery under higher line pressure, all while keeping an eye on the durability and recyclability of cartridges.

Monitoring is getting simpler and smarter. Inline pressure gauges, flow meters, and low‑cost conductivity or TDS sensors give quick performance clues. While a single number never tells the whole story, trends do: stable flow, consistent taste, and punctual filter changes are hallmarks of a healthy system. Remote alerts and compact data loggers are emerging, allowing households to spot leaks or unusual demand patterns early. The most valuable innovation, however, may be user‑centered design—clear labeling, tool‑less housings, and transparent capacity ratings that make correct maintenance almost effortless.

Material science is pushing boundaries in selectivity and longevity. Advanced carbons with tailored pore structures target difficult organics more efficiently. Next‑generation membranes aim to reduce fouling, enabling higher throughput at lower pressures. There is also growing attention to filters that specifically address persistent chemicals while minimizing energy use and waste. As these options mature, expect more systems that deliver high removal where needed and gracefully step back where simpler media will do.

For homeowners and renters alike, the takeaway is practical and encouraging:

– Test first, choose second; let data steer spending.

– Keep the chain simple: sediment for protection, carbon for taste, plus a targeted barrier if testing calls for it.

– Plan maintenance into your calendar and budget from day one.

– Revisit your setup annually; water quality and household needs change.

Filtration is not about chasing perfection; it’s about confidence in what you drink and depend on daily. With a clear goal, a matched technology, and a maintenance plan you’ll actually follow, you can improve water quality meaningfully, reduce waste, and make every glass a quiet confirmation that your system is working as intended.